Innovators Of Container-Based Modular Structures

SG Blocks is a leading designer, innovator, and fabricator of container-based modular structures including residential and commercial projects, military, and healthcare. We give a big thank you to Steve Armstrong, the Chief Technology Officer of SG Blocks for joining the Tiny House Alliance USA, and contributing to our mission of affordable housing.

SG Blocks can in build two ways. In addition to their signature container-based construction, they also offer solutions with wood construction, all in line with their principles to make any project more affordable, efficient, and sustainable.

The SG Blocks manufacturing facility is in Durant, Oklahoma, 1.5 hours from Dallas, TX. SG Echo is proud to have 70,000 sq ft of manufacturing space on a 19-acre campus, with a skilled labor and production planning group that is capable of meeting strict building requirements on time and on budget.

Three Core Deliverables

SG Blocks works with clients large and small with many verticals. With this being said, no matter what you ask for, expect it to be done right, on time, and on budget. From providing a structural core and shell to completing turn key deliverables, SG Blocks can help ensure your project is a success.

1): Green Steel

GreenSteel is the structural core and shell of an SG Blocks building. The entry-level delivery method includes the following: procurement of containers, all required openings for doors, windows, MEP connections, full sidewalls to allow for large open spaces, structural steel reinforcements (as required around all openings to meet code and surpass safety requirements), and a fresh coat of paint in nearly any color imaginable. The units are delivered to the site where they are offloaded and handed over to a local GC to finish to specifications.

2): Partial Prefabrication

Selected materials, finishes, and systems are installed at an SG Blocks facility, with the balance completed on site by the general contractor.

3): Full Prefabrication

This is their ready-made solution. SG Blocks delivers a fit-out product where we erect the final units on-site and complete all trim outs and closure pieces, so it is ready to occupy. For full modular, the project contractor completes the foundations and site work in preparation for unit delivery.

ConGlobal is North America's largest full-service supplier to the intermodal industry and leading retailer of new and used containers.

SG Blocks has an exclusive container supplier relationship with ConGlobal that has been extended until 2024. The key is that SG Blocks is now leveraging ConGlobal’s greater scale and sales force absent the cost of having to pay for them. This is big, SG Blocks executed almost $10M in contracts in the last year with just two sales people, what could happen as they leverage an additional 30-40 now partnered with ConGlobal?

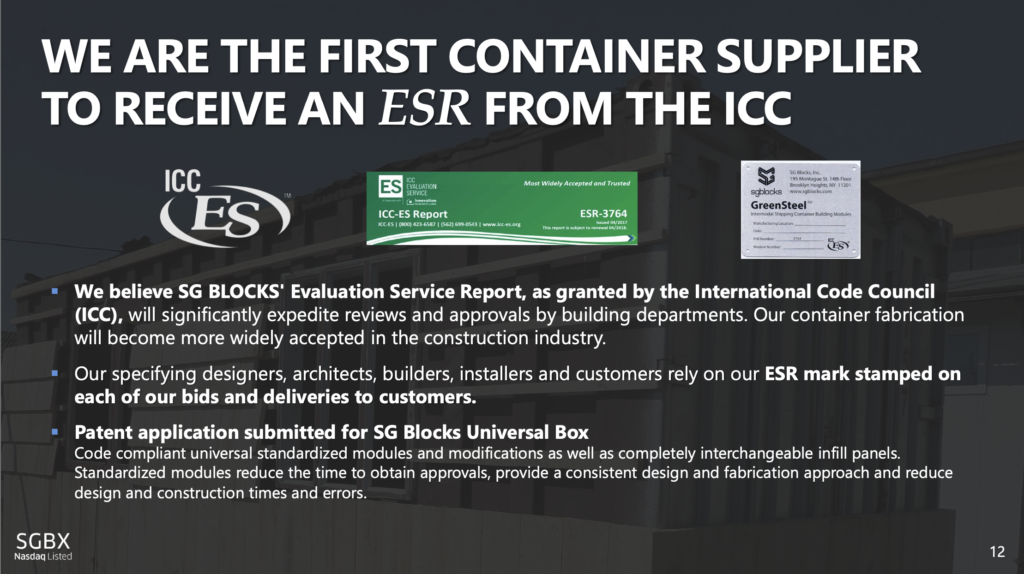

SG Block Has Set The Standard

SG Blocks First to be Evaluated to Requirements of New ICC-ES Acceptance Criteria (AC462) for Structural Building Materials from Shipping Containers

While SG Blocks was the first to receive an ESR from the ICC, we are now one of a few select handful of companies.

Shipping containers to be used as the source of structural and non-structural building materials for constructing building modules

ICC Evaluation Service (ICC-ES)—the experts in building product evaluation and certification—has issued ESR-3764 to SG Blocks for their Structural Building Material from Shipping Containers, providing evidence they comply with the code requirements of the 2015 International Building Codes® (IBC) and International Residential Codes® (IRC).

SG Blocks Building Modules are site specific, custom designed, factory built modules that are transported to a jobsite and assembled to form a completed building. Shipping containers are used as the source of structural and non-structural building materials for constructing the building modules. Steel structural building materials from the shipping containers and the quality control process for selecting shipping containers is the subject of this report.

“As the built industry develops new and innovative ways to do construction, so does ICC-ES, by working diligently with our ICC-ES committee and technical staff to develop new acceptance criteria for products not covered in the International Code.” said ICC-ES Senior Staff Engineer Woods McRoy, P.E. “Manufacturers are able to accelerate their products speed to market with the assurance and rigorous technical evaluation that ICC-ES is known for.”

“ICC-ES worked thoroughly and efficiently in developing AC462 and Issuing ESR-3764.” said SG Blocks CTO, Steve Armstrong, “We are pleased to be the first manufacturer in our industry to meet the latest code requirements, and look forward to working with ICC-ES again. This is a major step in mainstreaming the use of container based structures in the industry.”

Build Better, Stronger, Faster, And Greener With Blocks

SG Blocks helps builders save time and money, giving builders of every size a competitive advantage on any project. Not only can you offer your clients greener and more sustainable solutions, but you can dramatically reduce the time and cost which in turn, gives you more opportunity to grow your business.

Commercial

Residential

Competition is increasing and brand engagement is becoming more important than ever, building large new stores in unproven locations is expensive, and marketing costs can be even more costly. Going where your customers already are is a better strategy for creating long-term brand engagement.

SG Blocks works with some of the world’s leading retailers develop unique and engaging brand experiences with small footprints that are creative and innovative, such as mobile retail pop-up structures.

Millions of acres of forest are depleted every year, much of it harvested for building. In contrast, containers and prefabricated modular construction can substantially offset a development’s carbon footprint and reduce the use of natural resources. All of SG Blocks’ container and prefabricated options are strong, resilient, and can reduce construction time by up to 40%. Hard and soft costs are lower as well, particularly in expensive urban and mid-rise markets.

It’s time to start building smarter and better. With SG HOME, you can have a beautiful, newly constructed home using sustainable materials. Housing prices start at just $90,000 and all are available with a range of finishes, inside and out.

Military

SG Blocks consistently meets or exceeds exacting military demands while saving money. The company has a history of providing unique solutions for everything from mobile offices for aircraft carriers in dock, to new barracks for soldiers, all tailored to the stringent needs of the military while saving critical dollars.

Medical-Healthcare

SG Blocks has partnered with Grimshaw Architects to create a suite of efficient and reliable on-site COVID-19 Testing Pods. These turn-key testing and lab facilities are housed completely in a container-based structure that can be set up virtually anywhere on the planet, then moved as needed. All of these structures are designed for a safe and comfortable COVID-19 testing experience for both patients and medical staff, accommodating both small and large testing groups in order to deliver accurate and timely test results.

SG Blocks, Inc. (NASDAQ: SGBX) (“SG Blocks” or the “Company”), a leading designer, innovator and fabricator of container-based structures, announced today that the Company is working in tandem with Stone Clinical Laboratories to bring COVID-19 testing to Miami’s South Beach area, on behalf of Food Network’s annual Wine & Food Festival.

Sizes Available

How High Can SG Blocks Build?

While there are numerous size and type applications of intermodal containers, the cornerstone of the SG Blocks Building System is the “dry freight” container. Dry freight containers come in standard heights (8’6”) for 20’ and 40’ units with 40’ units also available in high cubes (9’6”). High cube containers are most suitable for construction.

SG Blocks maritime grade containers can be stacked 9 high. We can also work with you to achieve the story count you need (coupled with other considerations in cost and code compliance) for the most effective building.

What Types Of Facades And Finishes

LEED Certification

SG Blocks can work with any facades used in traditional construction including limestone, stucco, shingles, brownstone, brick , and aluminum siding. We work with standard or custom finishes throughout and fit doors and windows to meet the customer’s design.

SG Blocks helps by contributing recycling points, new technologies, and proximity from project site. While each project individually achieves a LEED certification rating, (based on a wide variety of equipment choices, site design, and building layout), our product always contributes to the bottom line.

Foundations

What Is The Cost?

There really is no difference between conventional construction and container-based construction in terms of foundations. Any type of foundation system used in a particular area that is dictated by the subsurface soil conditions can be used.

SG Blocks has delivered structures that range from simple to complex. Without knowing any specifics on your project, the best they can provide is a baseline. Our entry level product (Green Steel only), begins at $30 per square foot for a simple one story application and the price then rises proportionately for mid-rise, elevated, and sprinkled structures. Costs increase based on complexity of design and scope of work SG Blocks is to perform.

Smoky Park Supper Club In Asheville, North Carolina

A Restaurant Constructed from 19 Salvaged Shipping Containers

This 6,000-square-foot prefab design in Asheville, North Carolina, features artwork and furniture crafted by locals.

In a poetic twist, the site of the Smoky Park Supper Club in Asheville, North Carolina was once a dumping ground sandwiched between a bridge of the same name and a railway. The site’s owner envisioned a more sustainable approach to the land: he wanted to build a restaurant. The eatery he had in mind would be made entirely of salvaged shipping containers fastened together like oversized Legos in a sprawling, unified design. Project architect Myles Alexander of Form and Function Architecture had used this material before, albeit for the local county school system’s storage facilities and as accessories for private clients. He set out to “provide an experience that was as raw as possible.” Nineteen containers were repurposed to let in sunlight while maintaining the most of their structural integrity. On the inside, in solidarity with the surrounding River Arts District, the works of a local muralist and craftsmen add warmth to the space.

Certified By PFS TECO